MINIMIZING COST OVERRUNS IN HEAVILY ENGINEERED FIRST-OF-CLASS PRODUCTS

By Michael W. Jones, John Holmander, Jim Hughes, and Andrew Miller

October 22, 2021

It happens so often: a new heavy industrial program is launched, progress reviews show everything is on track, and yet, somehow, the project ends up over-budget and late. This happens repeatedly: across industries, contractors or manufacturers, owners, and decades. While the cost increases may appear to occur in later stages of the project, they start much earlier – even at the very beginning.

One of the most significant root causes is late design products, which impact throughout the program and are visible most prominently in the later stages, after “easy” workarounds and management reserves have often been exhausted. When the cost increase becomes clear, it is too late to mitigate it: cost-minimizing practices must be present from the start. MW JONES & COMPANY has identified five simple steps that can help avoid these problems and keep a program on-track from the outset.

Heavy Industrial Programs Consistently Overrun Budgets

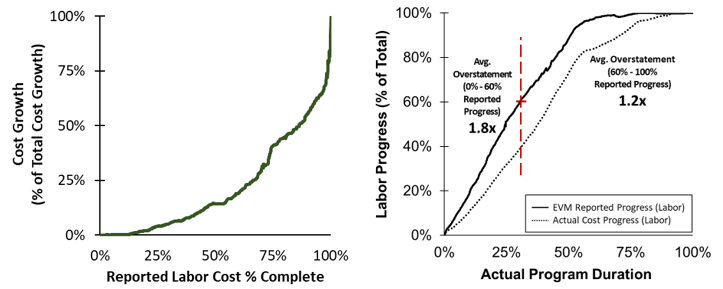

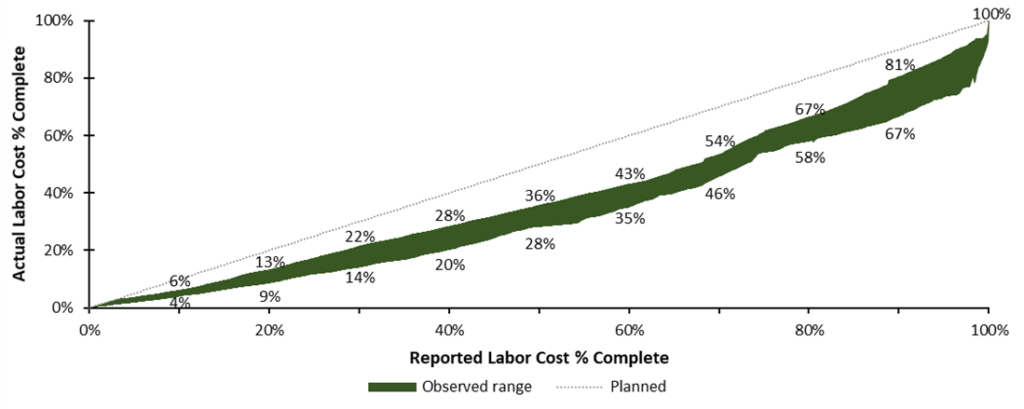

It’s no secret that heavily engineered, first-of-class products consistently overrun their budgets (Figure 1). The U.S. Department of Defense reports that first-of-class (“development”) programs see cost increases averaging 14.9% (compared with no growth on follow-on (“production”) programs), and the U.S. Government Accountability Office found that the average first-of-class ship exceeds its budget by 52%, compared with only 8% for the average follow-on ship. To make matters worse, the cost growth is late stage: ~85% of labor cost growth on first-of-class ships occurs in the last 40% of progress, and ~45% occurs in the last 10% of progress. As a result, heavy industrial programs typically fall behind the cost curve and don’t even realize it (Figure 2).

Figure 1. Heavily engineered, first-of-class products consistently overrun their budgets. Contract budgets can double (or more) over the course of manufacturing, leading to chronic under-reporting of actual cost progress.

(Source: Defense industry case studies as analyzed by MWJ&CO)

Figure 2. Companies over-estimate % complete from the start. The persistent gap between actual and planned labor cost % complete shows that companies often do not realize they are over budget.

(Source: Defense industry case studies as analyzed by MWJ&CO)

Late Design Deliverables Create Cost Overruns

Cost overruns in heavily engineered products have many causes, including one company designing a product that is then manufactured by another, supplier industrial base challenges, poor planning, immature technologies, vague requirements, poor program management, poor change control, inexperienced labor, new tools, an unrealistic cost baseline, and late design. Of these, late design deliverables is the most prevalent and consistently occurs in programs with cost overruns (75% of U.S. Department of Defense programs with Nunn-McCurdy breaches experienced late design).

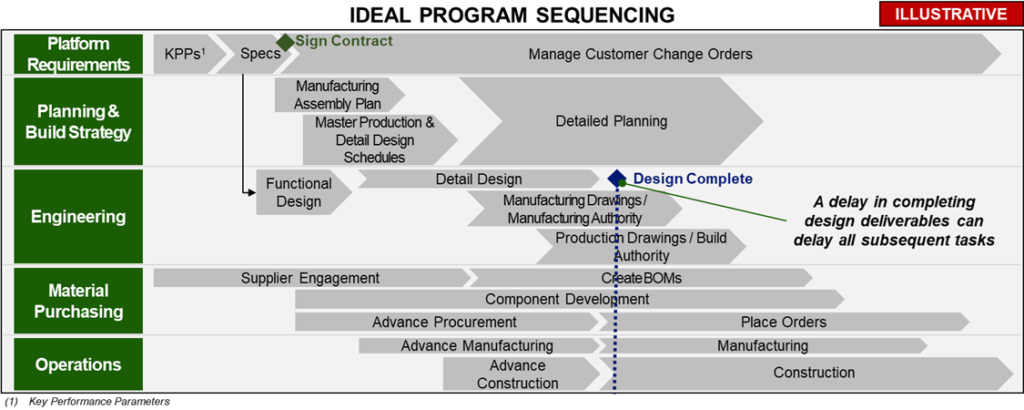

Figure 3. The ideal program schedule is highly interdependent, with many activities happening in parallel. While compressed schedules deliver the program in the shortest time possible, they have little ability to accommodate delays – increasing cost risk.

Late design deliverables delay build authority (production drawings), material purchases, and, by extension, manufacturing and construction (Figure 3). Heavy industrial program schedules are highly interdependent, with design and manufacturing as parallel as possible to accelerate product delivery (subject to available industrial capacity and funding; production costs may need to shift into the design phase to support planning and material opportunities). This leaves very little tolerance for delayed design: the downstream impacts can be 1-for-1 (1 day of delay for every day of design delay).

Five Opportunities for Contractors or Manufacturers to Arrest Cost Growth

Five strategies can help contractors or manufacturers minimize late design products and cost growth:

- Manage and control design development process and tools, and ensure linkage to the production schedule

- Establish enterprise business rules, standard offsets, and strong value-stream performance measures

- Implement a strong material forecasting process in advance of design completion to identify and accelerate material purchasing

- Develop Management Reserve (MR) and Undistributed Budget (UB) strategies for unknown scope growth

- Develop a robust work-timing and staffing alignment process to ensure manpower matches the work that can be made available

These five actions can result in significant risk reduction, early identification of issues, early understanding of root causes, and timely implementation of preventative actions to prevent those issues from reoccurring – even to the point that cost growth slows and reflects a follow-on program instead of a first-of-class program.

- Manage and control design development process and tools, and ensure linkage to the production schedule

When possible, the best way to manage a risk is to avoid it. Leading firms implement an integrated design/build process that links design, build strategy, material purchasing, and construction, including vendors and design subcontractors. This results in up to 4x fewer design errors – and associated schedule and cost impacts – than in programs that separate design from build.

These firms use norms to estimate and manage the design effort: each piece-part has cost, quality, and schedule norms based on type, discipline, and design maturity phase. They minimize and manage implementation of new tools (integrated into the program schedule) and use an integrated process and schedule across engineering, materials, component development, build planning, construction, and integrated system testing. Dependencies are based on earliest schedule need dates. Engineering development models and prototypes validate the design before build starts.

In execution, they manage vendors and design subcontractors tightly to coordinate interdependencies. They tie engineering and planning errors discovered during production back to design to identify (and pre-empt) other, similar failures. They implement a robust change control board that requires all changes, their root causes, and total impacts to be fully understood before approval. After approval, they take action to prevent future recurrence.

- Establish enterprise business rules, standard offsets, and strong value-stream performance measures

While program schedules are compressed, standard offsets and other enterprise business rules provide advance warning of late design to let the factory re-plan. Leading firms establish offsets for design completion, work order creation, and material delivery, based on their industry and business rhythm. For example, in shipbuilding, best-in-class offsets include 52 weeks between a module’s design disclosure and activity start, 26 weeks from a module’s work package issuance to activity start, and 12 weeks between the material being ready in yard and activity start.

Once the offsets are established, engineering, planning, and material purchasing processes must support them, and work sequencing must match up against the factory’s staffing plan (to avoid an idle “standing army”).

- Implement a strong material forecasting process in advance of design completion to identify and accelerate material purchasing

To reduce the impact of material lead time, leading firms order materials before the arrangement design is complete (and after component design is complete), expeditiously pulling materials from the design to give vendors adequate lead time. These firms have a robust material quantity forecast that uses the Engineering BOM (EBOM) and engineering quantity estimates to order materials early. The forecast is refined by a series of “Material Takeoffs” performed throughout the design effort. If the program schedule does not support the material delivery offsets, these firms work with their customers to implement an Advanced Procurement program (sometimes with an Advanced Construction program to prototype new processes and materials).

Leading firms base material ordering and delivery on the first use and total material usage. This ensures they get the most supplier leverage possible with economic order quantity buys.

- Develop Management Reserve (MR) and Undistributed Budget (UB) strategies for unknown scope growth

Most programs have Management Reserve, and leading firms anticipate late-stage cost growth and build that into their Management Reserve and Unplanned Budget strategy. This strategy is in 3 parts: align with customers, plan for unanticipated costs, and tightly manage funding release.

Leading firms are aligned with their customers on the importance of a strong management reserve to absorb first-of-class cost overruns. This alignment reduces friction when the MR is carved out from the Performance Measurement Baseline (PMB) at the start of the program.

Leading firms also plan for unanticipated costs, like using planning packages to anticipate future cost growth (e.g. allocate 6% of PMB to a post-launch planning package in anticipation of unplanned costs), and build UB, which is distinct from MR, into their PMB (this has two benefits: UB is included in standard performance metrics like CPI and CV, and it also is not perceived as a “stealth” fee).

Leading firms tightly manage funding release. While individual functions release their UB, they allocate it before a task starts. The PMO tightly manages MR release (e.g., change control board releases MR, MR is not used to fix errors in customer-provided design or for poor performance) and reserves most MR until later in the build to accommodate both out of sequence work and the rework caused by late design.

- Develop a robust work-timing and staffing alignment process to ensure manpower matches the work that can be made available

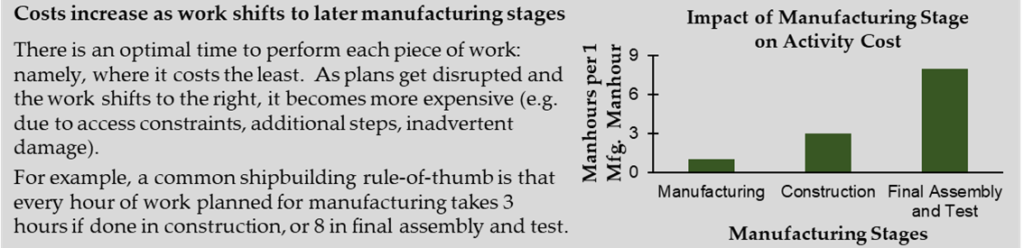

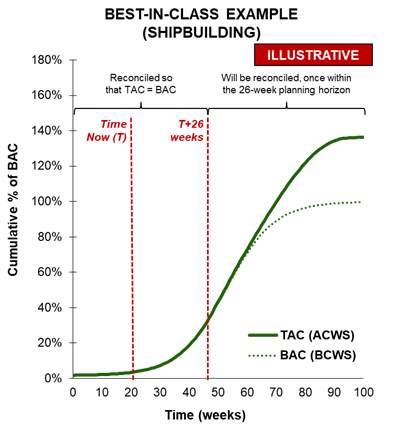

By using standard offsets, leading firms reconcile the work that can be made available with their manpower – adjusting either so that the factory doesn’t cost more than the program can afford (Figure 4). This starts with knowing the manpower planning horizon: the time needed to accelerate work, hire additional workers, or lay-off workers (e.g., in shipbuilding, this is typically 26 weeks).

Leading firms have a weekly process that looks out to that horizon, identifying all effort needed to perform that week’s activities (using the bid’s trade-specific norms / standards) and comparing it with the labor hours in the budget for the same activity. Variances of more than 5-10% (depending on stage) are highlighted to the PMO, which works to reduce the workforce if additional work cannot be pulled forward and workers cannot be reallocated to other programs.

Figure 4. Without a robust staffing alignment process, costs can grow. Leading firms ensure manpower matches work available.

Conclusion

Minimizing cost overruns in heavily engineered first-of-class products is challenging and requires enterprise-wide focus and activity. By focusing on these five initiatives to keep design on-time and manage the impacts when it is delayed, firms can better manage risks, control costs, and improve project ROIs.

Primary sources include: Performance of the Defense Acquisition System (2019); Performance of the Defense Acquisition System (2016); GAO reports GAO-07-943T, GAO-05-183, GAO-18-238SP; and MWJ&CO analysis of defense industry case studies

Photo credits: US Navy, Oshkosh Defense, BreakingDefense.com, iNews