THROUGH-LIFE COST AND THE CANADIAN PATROL SUBMARINE PROJECT

By Michael W. Jones, Jim Hughes, John Holmander, and Andrew Miller

October 17, 2022

As the Canadian Patrol Submarine Project considers how to best replace the Victoria-class and deliver the military capabilities that Canada could need in this period of great-power conflict, cost is likely top-of-mind for many – and, if history is a guide, could heavily influence Canada’s decision given the need to define through-life costs as part of the acquisition approval process.

Given Canada’s requirement to assess through-life cost prior to acquisition approval and its historic focus on a “maintain in country” philosophy, comparing through-life cost for “maintain in country” and for “build and maintain in country” could help Canada select the most-beneficial path for the Canadian Patrol Submarine Project. After accounting for economic benefits, a fully domestic or hybrid build approach could possibly deliver economic impact that would make it equivalent to the cost of a foreign design-build; all of these options are likely favorable when compared with a nuclear submarine acquisition.

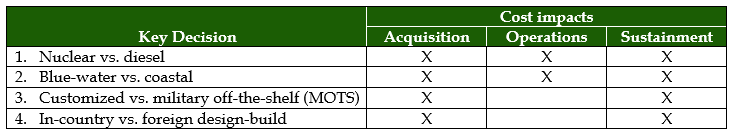

This analysis covers acquisition, operations, and sustainment costs – all of which are considered as part of Canada’s acquisition process. The acquisition cost includes designing and building the submarine and its infrastructure; operations cost includes crew and fuel; and sustainment cost includes maintenance, repair, overhaul, and modernization. While there are countless decisions that will influence through-life costs for the Canadian Patrol Submarine Project, this analysis considers four key decisions (Figure 1):

Figure 1: Key acquisition decisions and cost categories impacted.

Given the size and importance of acquisition cost, this article focuses on it and applies parametrics to estimate operations and sustainment costs.

Nuclear vs. Diesel

The Nuclear vs. Diesel decision influences acquisition cost (e.g., propulsion system), operations cost (e.g., larger crew), and sustainment cost (e.g., specialized monitoring of nuclear-related systems), as well as the operating capabilities of the submarines themselves.

From a capability standpoint, nuclear submarines are better-suited for stealthy transit and under-ice operations, have a faster transit speed (translating to more on-station days per cruise), and have more space for special operations forces equipment (amongst other benefits).

Looking at costs, we first consider fleet size. A 2016 Auditor General of Canada report[1] stated that Canada desires 420 sea days per year – based on current maintenance cycles and crew tempo considerations, we estimate that Canada would need 5-8 submarines (4-6 operational and 1-2 in maintenance), either diesel or nuclear, to achieve that goal.[2] We also acknowledge that, depending on budgetary pressures, Canada may elect to acquire fewer submarines than would be needed to deliver 420 sea days per year. For this analysis, we assume Canada will acquire, operate, and sustain 5 submarines.

Next, we consider design life to ensure that the costs are comparable given different design lives for nuclear and diesel submarines. The Virginia class’s design life is ~33 years and modern diesel submarines have a design life of ~30 years. Thus, to achieve the equivalent of ~33 capability years of one nuclear submarine, Canada would need ~1.1 diesel submarines. This implies that a fleet of 5 nuclear submarines, from a cost comparison perspective, is the equivalent of ~6 diesel submarines.

Finally, we consider infrastructure. The infrastructure required to support a fleet of nuclear submarines is more extensive than that required to support diesel submarines – in particular, a nuclear reactor is never “off” and requires shore-based infrastructure to support the reactor when the submarine is docked. Based on our experience, infrastructure to support nuclear fleets costs around twice as much as infrastructure to support diesel fleets.

For operations and sustainment costs, nuclear submarines have higher crew complements – 132 on the Virginia class vs. 48 on the Victoria class (or 42 on the Collins class) – but have lower fuel costs. In addition, some nuclear submarines no longer require a mid-life refueling – reducing sustainment requirements from those seen in earlier classes. Diesel-electric submarines are becoming more complex, with sophisticated battery and AIP systems that may increase sustainment costs.

Turning to the cost implications, we start with acquisition costs (including infrastructure). Based on recent estimates for nuclear submarines (e.g., ASPI’s Implementing Australia’s nuclear submarine program, December 2021), a fleet of 5 nuclear submarines (required to achieve at least 420 sea days per year) could have an acquisition cost of ~$100B+ CAD.

Considering operations and sustainment (O&S), relative acquisition and O&S costs can vary fairly dramatically by shipbuilding program and how costs are categorized, resulting in ranges from 40% acquisition and 60% O&S to the exact opposite, 60% acquisition and 40% O&S. To reflect this range, we use a general assumption that these two aspects of shipbuilding cost are relatively equal (50/50). However, given that crew costs (salaries, benefits, training, etc.) tend to be a fairly significant piece of most O&S cost assessments, we considered crew sizes in assessing various submarine options.

Applying this parametric, we estimate that a fleet of 5 nuclear submarines (required to achieve at least 420 sea days per year) could have a through-life cost of ~$200B+ CAD, compared with 5-70% of that number for diesel submarines.[3] The different combinations of the remaining 3 decisions contribute to the wide range.

Blue-water vs. Coastal

The second key decision that shapes the overall cost is the range of the submarine: blue-water or coastal. This is primarily a consideration for diesel submarines, as nuclear submarines are by default blue-water. Compared with blue-water submarines, coastal submarines are smaller and have shorter ranges – ideal for controlling waters near home ports. They are also more common, as the navies that value blue-water capabilities are predominantly nuclear.

Operations and sustainment implications include a smaller crew size for coastal submarines and the reduced maintenance costs that come with a smaller submarine.

The countries currently building diesel blue-water submarines – Japan, South Korea, and Spain – are doing so in their shipyards at a through-life cost ~15-55% of the potential through-life cost of a nuclear submarine fleet, compared with ~5-10% for those countries building diesel coastal submarines in their shipyards – including Germany and Sweden.

Public information about the Canadian Patrol Submarine Project indicates that Canada prefers a blue-water submarine for several reasons, including the potential ability to operate under ice and an operating range that reaches the Arctic from Esquimalt and Halifax (without assistance). A coastal submarine would require assistance (and that assistance may reduce the submarine fleet’s stealth) – such as a Heavy Lift Ship (HLS) that would transport the coastal submarine to the operations area, as proposed by Vice Admiral (Ret’d) Robert Davidson.[4]

Customized vs. Military Off-the-Shelf (MOTS)

The third key decision is how customized the submarine would be. Historically, Canada’s submarines have had minimal customization: the Oberon-class submarines were built by the U.K. for six navies, limiting customization, and, as the Victoria-class submarines were purchased used from the U.K., customization options were limited.

With the acquisition of new submarines, Canada will need to consider how customized or off-the-shelf their submarines will be. A MOTS approach would be the most consistent, on a spectrum from no customization to allowing more modest customization, like the combat system. The other option is more extensive customization, potentially including accommodating Canada’s unique environmental protection requirements.

Canada’s approach to contemporary naval acquisitions has been extensive customization (e.g., while based on BAE’s Type 26 design, the Canadian Surface Combatant has several Canada-only customizations; the Joint Support Ship, though based on the German Berlin-class, has been modified to allow replenishment from either side of the ship), and there may be temptation to do so with the Canadian Patrol Submarine Project.

Operations and sustainment implications of increased customization include additional training costs and, for unique customizations, increased sustainment costs from “parent navy” engineering and material efforts.

A MOTS, blue-water submarine fleet could have a through-life cost ~15-65% of the potential through-life cost of a nuclear submarine fleet, while a customized, blue-water submarine could be ~25-70%.

In-country vs. Foreign Design-Build

The final decision we consider that shapes the potential through-life cost is how much of the submarine is designed and built in-country vs. abroad. Besides all-foreign or all-in-country, there are a range of hybrid options, each of which has its own cost and risk profiles.

This decision on acquisition approach impacts sustainment costs. National security concerns mean it is likely that Canada would perform in-service support domestically – as it does with the Victoria class. Creating a domestic sustainment capability (supply chain, workforce of suitably qualified and experienced personnel (SQEP)) can be done by building part (or all) of the submarines in Canada, or as part of the in-service support effort – but it must be done either way.

While Canada has not built submarines since the early 1900s, it does perform all sustainment for the Victoria-class. Thus, at a minimum, some portion of submarine construction (e.g., final outfitting, module construction excluding the pressure hull) or, potentially, construction of an entire submarine, could be performed in Canada.

While there is a cost premium to building a foreign submarine design in-country, much of that premium is spent domestically, creating further economic benefit. For example, an economic analysis identified that every $1 spent on in-country shipbuilding generated $1.30 in economic impact.[5]

A foreign build of a blue-water diesel submarine could have a through-life cost 15-55% of the potential through-life cost of a nuclear submarine fleet. On paper, an in-country build could appear to be 40-50% more expensive than a foreign build, but this is before accounting for the economic benefit of domestic spending (in both scenarios, as infrastructure, operations, and sustainment would be domestic spend regardless of where the submarine is built), which could be 30% on an in-country build and 25% on a hybrid in-country / foreign build.

After accounting for that economic benefit, both an in-country build and a hybrid in-country / foreign build of a blue-water diesel submarine could have similar through-life costs as that of a foreign build (20-70% of the potential through-life cost of a nuclear submarine fleet, depending on operational and acquisition decisions). This could create a path for the economic impacts of domestic construction and sustainment to reduce or neutralize the additional costs of building in-country.

Conclusion

Canada has many paths to reaching an affordable submarine acquisition. While diesel submarines are a fraction of the cost of a nuclear fleet, a nuclear option is certainly not out of the realm of possibility. However, it is highly unlikely given Canada’s historic acquisition approaches.

After accounting for economic benefits, a fully domestic or hybrid build approach could possibly deliver economic impact that would make it equivalent to the cost of a foreign design-build; all of these options are likely favorable when compared with a nuclear submarine acquisition.

Resources:

[1] 2016 Fall Reports of the Auditor General of Canada, Report 7—Operating and Maintenance Support for Military Equipment—National Defence, accessed at https://www.oag-bvg.gc.ca/internet/English/parl_oag_201611_07_e_41836.html

[2] The range of submarines is based on different assumptions for sea days per year. 5 submarines would be required if each submarine could achieve 105 sea days per year (4 active submarines, 1 in maintenance; 105 sea days is within Canada’s maximum of 120 days). 8 submarines would be required (6 operational, 2 in maintenance) if each submarine is limited to the Victoria class’s median performance of 77 sea days per year (2012-18; see https://www.canada.ca/en/department-national-defence/corporate/reports-publications/proactive-disclosure/secd-state-of-caf-19-april-2021/q-433-victoria-class-submarines.html for historic Victoria-class sea days per year).

[3] Normalized for service life and after accounting for economic benefit of domestic spend. Cost estimates are based on public data and an MWJ&CO through-life cost model.

[4] Davidson, Robert, “Submarine Procurement: Widening the Aperture of Options”, Starshell March 2022.

[5] Testimony of Kevin Mooney to the Standing Committee on Government Operations and Estimates, May 10, 2022 (https://publications.gc.ca/collections/collection_2022/parl/xc70-1/XC70-1-2-441-19-eng.pdf)

Photo credit: The Canadian Press